Manufacturing Process

The care behind each soap

Each soap is born from a meticulous process, where attention to detail is ever-present.

Centuries of experience guide skilled hands, preserving techniques that span generations.

The result is unique products, where quality, aesthetics, and essence come together in perfect harmony.

MANUFACTURING PROCESS

MIXING

The ingredients are combined with care and mastery, creating a uniform mass ready to take shape.

LAMINATION

The mass passes through rollers that smooth and align it, creating a consistent texture, perfect in every detail.

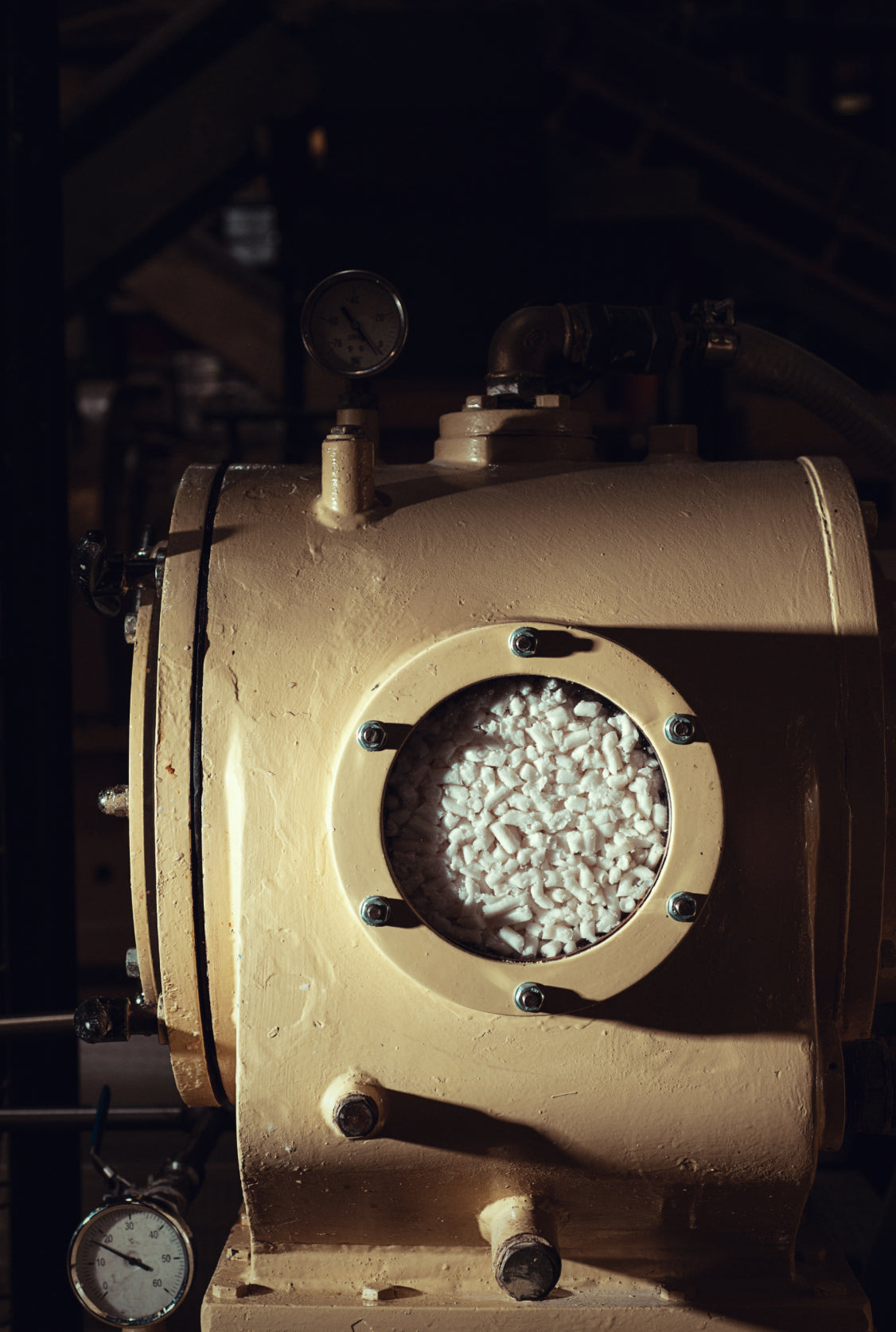

EXTRUSION

The soap bar is compressed and purified, removing air and reinforcing its density and durability.

CUTTING

The bar is carefully cut into individual pieces, each with strictly controlled proportions and size.

STAMPING

In the molds, each soap receives its final shape and the engraved logo, signing the brand’s identity.

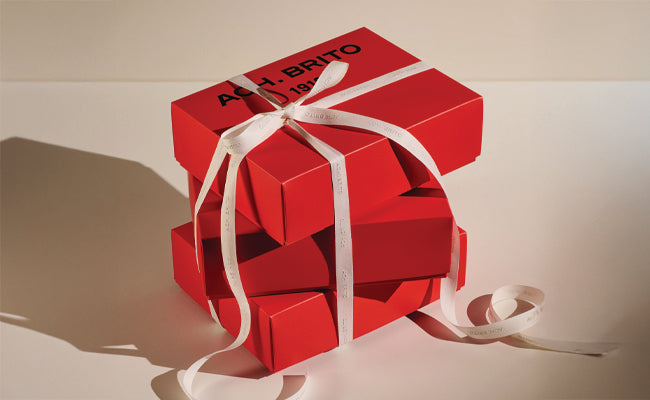

PACKAGING

The final packaging requires delicacy and technique, whether done by hand or mechanically, preserving the perfection of each soap.

Bottles that tell stories

We celebrate the art of conveying emotions without words. Like literature, fragrances transport, inspire, and connect us to what is most intimate.

For over a hundred years, the green Lavanda bottles have taken shape at Vista Alegre Atlantis, a historic partner of ACH. BRITO. Since the first launch, production has followed the same careful and meticulous method, transforming each piece into a true ex-libris of the art of glass. Each bottle preserves the authenticity, delicacy, and character that make the brand a timeless ico

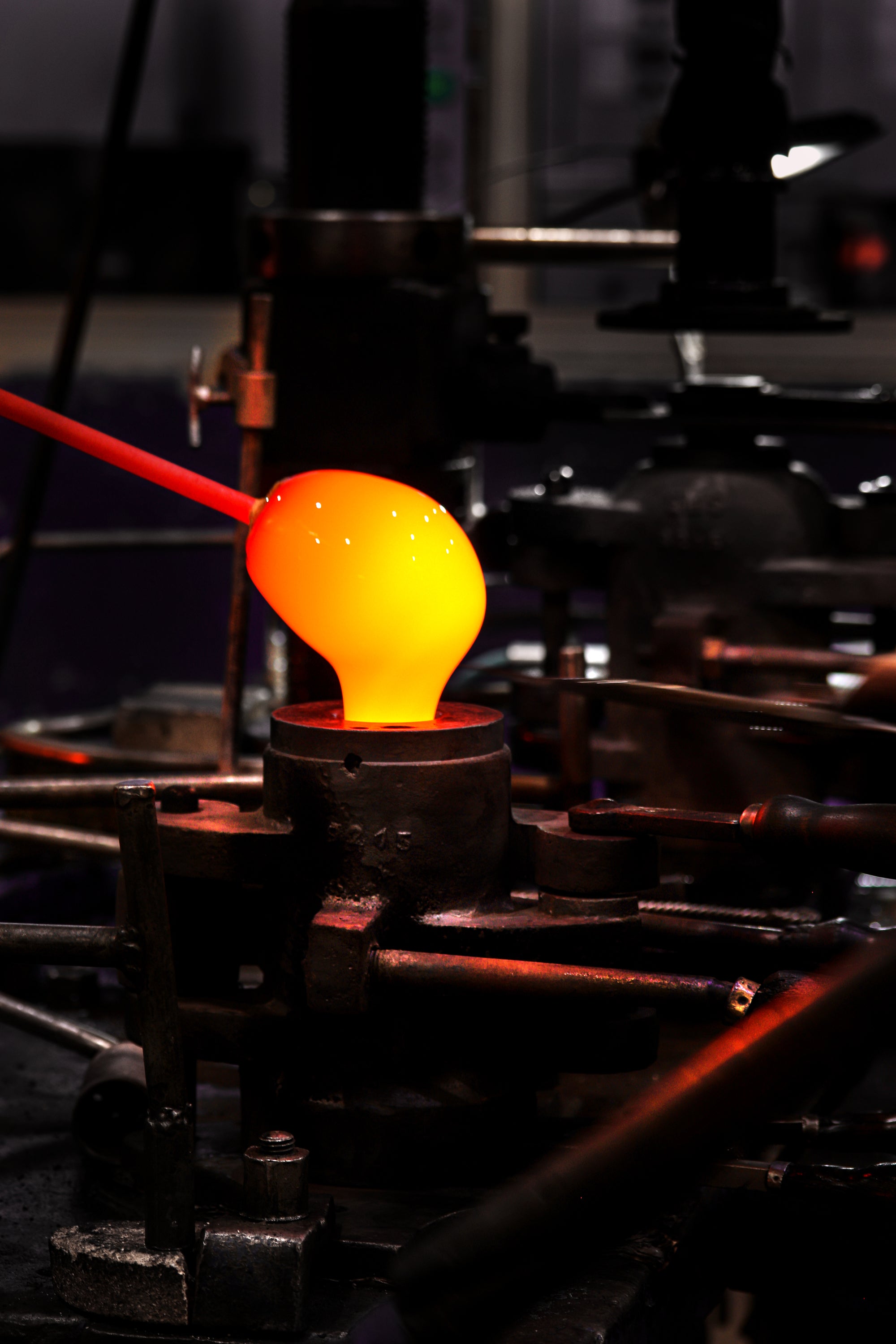

MATERIAL GATHERING

The master glassmaker manually collects the molten glass mass from the furnace, capturing the incandescent glass to ensure raw material of the highest quality.

FEEDING THE INITIAL MOLD

The glass mass is carefully deposited into the initial mold (Blank Mould), cutting the portion needed to create the outline of the piece.

OUTLINE FORMATION

The outline, called the parison, is shaped in the initial mold and manually transferred to the final mold (Blow Mould), where it gains its definitive shape with the artisan’s blow.

COOLING AND CONTROL

The piece begins controlled cooling (annealing) to ensure stability. A visual inspection and volumetric control follow, guaranteeing the final quality of each bottle.